- Home

-

Vinyl & more..

-

Heat Transfer Vinyl (Textiles)

>

- Vinyl & Letter Remover

- PU-FLEX 20in HTV

- PU-FLEX 13in HTV

- Easyweed 12in

- Easyweed Stretch 15in

- Easyweed Extra - Nylon

- Easyweed Electric 15in

- GLITTER Vinyl 20in

- Patterns HTV

- METALLIC & FOILS Vinyl 20in

- Glow in the Dark HTV

- Reflective HTV

- FLOCK HTV Vinyl

- Brick & PUFF 3D Vinyl

- Dye Sublimation Vinyl

- Printable Vinyl (Eco-Solvent)

- Transfer Application Tape

- T-Shirts & Blanks >

- Vinyl Cutters & Supplies

- Heat Transfer Press >

- Heat Press Accessories

- PSV Permanent Sticker - YARD

- Printable Sticker Vinyl

- Inkjet Transfer - Paper

- Sublimation Paper & Blanks

- Inkjet Printable - Vinyl

- Laser Transfer - Paper >

- Plastisol Transfer - Paper

- Screen Print Foils

-

Heat Transfer Vinyl (Textiles)

>

-

Inks & Supplies

-

Plastisol Inks

>

- Whites & Black

- Additives & Bases

- AP - All Purpose Inks

- HO/LB - Poly Low Bleed Inks

- LC - Low Cure Inks

- 4C - Process Inks

- SPT - SPOT Process Inks

- FL - Fluorescent Inks

- TF - HotSplit Transfer Inks

- GT - Glitter Inks

- MET - Shimmer & Metallics

- PMS - Pantone Colors

- PIM - PMS Mixing System

- REF - Reflective Inks

- PHS - Glow in the Dark

- PHC - Photo-Chromatic Inks

- SXF - Special Effects Inks

- Pad Printing Inks

- Latex Inks - Balloons

- Waterbase Inks

- Adhesives

- Spot Removers/ Cleaners

- Chemicals/Reclaim

- Emulsions

- Aluminum Frames

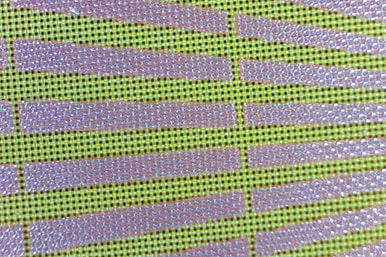

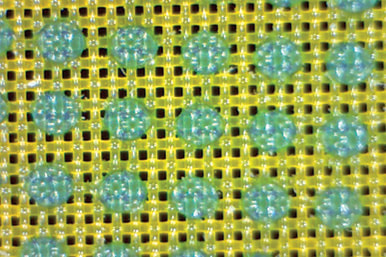

- Mesh for Screens

- Squeegees

- Screen Printing Supplies

- Output Film - Inkjet/Laser

- Color Separation Programs

-

Plastisol Inks

>

-

Equipment

-

DTF & UVDTF

- Gang Sheet Builder for DTF

- How to setup DTF Gang sheet

- Specs for DTF & UVDTF

- DTF Stock Designs

- DTF Printers >

- DTF Ink & Supplies

- UV DTF Printers >

- UV DTF Supplies

- Sublimation Printers >

- Mimaki Wide Format Printers >

- Heated Laminator

- Inkjet Printers

- Laser White Toner Printers >

- Vinyl Plotters/Cutters >

- Financing

- Specials

- Training

- Trade Shows

- Contact us

Frequently asked Questions

Q: I'm interested in starting up a screen printing business at home. I am curious how much space is recommended for doing this?

A: At least half of screen printers start in their homes, perhaps in a garage, basement or building in the back yard. You need about a 20' x 20' area to work comfortably. You can do it in less space, and more is better, but that's what you really need. Aside from production, you'll also need some storage space. This will vary depending on how many orders you do per week and how large the orders are. But you will have to have some place to put boxes of blank shirts until they are printed and then a place to put finished orders before they are shipped out.

A: At least half of screen printers start in their homes, perhaps in a garage, basement or building in the back yard. You need about a 20' x 20' area to work comfortably. You can do it in less space, and more is better, but that's what you really need. Aside from production, you'll also need some storage space. This will vary depending on how many orders you do per week and how large the orders are. But you will have to have some place to put boxes of blank shirts until they are printed and then a place to put finished orders before they are shipped out.

|

Besides storage space, you'll also want dedicated areas for staging screens, if possible. Screens are delicate, so you don't want them lying around. If space is an issue for your start-up shop, there are space-saving options available in equipment. For example, some manufacturers offer an exposure system that can be placed on top of something else like a screen drying cabinet. So you are able to stack two pieces of equipment in one space. Be sure to research the many options available as you shop for equipment.

|

|

Q: I'm going to a trade show to check out purchasing my first manual press.

Any suggestions on what I should be looking for? A: When shopping for equipment, industry trade shows are a great place where you can talk with suppliers, see equipment in action, and get recommendations from other decorators. You may also want to ask your supplier for a list of its customers, and stop by some shops for a visit to get feedback on the equipment. You also can get recommendations on industry forums, where you can find candid feedback from decorators. When checking out a press in person, look closely at its structural stability. |

Feel the machine, spin it, push down on the pallets, and get a sense of how well it's built. In many ways, it's much like taking a car for a test drive; you're trying to get a sense of how it feels to use it. You'll spend a lot of hours spinning those pallets so make sure you like the feel.

Also, look closely at the construction of the pallet, whether it is made from wood, steel, or aluminum. Wood is inexpensive but can warp easily and costs more in the long run as you're forced to replace pallets. Aluminum is a good choice, although steel is, of course, a stronger material and dissipates heat better. Some pallets also are covered in rubber, which protects them and provides a firmer grip to hold garments in place. Finally, ask the supplier about the warranty he offers.

Also, look closely at the construction of the pallet, whether it is made from wood, steel, or aluminum. Wood is inexpensive but can warp easily and costs more in the long run as you're forced to replace pallets. Aluminum is a good choice, although steel is, of course, a stronger material and dissipates heat better. Some pallets also are covered in rubber, which protects them and provides a firmer grip to hold garments in place. Finally, ask the supplier about the warranty he offers.

|

Q: Can you use a flash cure to cure instead of a conveyor dryer?

A: You can use a Flash Cure unit vs. a Conveyor Dryer, however, it will lower your production. You must be more watchful when using a Flash unit in order to make sure you do not over cure it or under cure your ink. Most Plastisol inks cure once they reach 320F, you will need to Flash for approx. 30-45 secs. depending on the distance of the panel from the surface of the T-shirt. Use a Temp Probe to check you are getting the correct temperature.

|

|

You can also Flash cure for 10sec. and complete the curing with your Heat Press using 320F @ 15secs. **Make sure you use a Teflon Sheet.

Production estimates are based on how fast you can cure your T-Shirts, using a Conveyor dryer will allow you to output 75-125 shirts per hour depending on your conveyor size.

Implementing a Flash unit with Rotary Tables increases production to 25-30 pcs. per hr. |

Q: What temperature does the ink need to hit to cure properly?

A: Most Plastisol inks require 320F to properly cure, but it really depends on what you are doing too. Keep in mind that ink deposit plays an important in how fast the ink can cure, and also Reflective, Metallic & Waterbase inks may require a longer time in the heat to fully cure.

A: Most Plastisol inks require 320F to properly cure, but it really depends on what you are doing too. Keep in mind that ink deposit plays an important in how fast the ink can cure, and also Reflective, Metallic & Waterbase inks may require a longer time in the heat to fully cure.

|

We offer Temperature Probes and Temp Labels to check for the proper curing temperature.

Click here for Temperature testing options |

Q: How do I pick a conveyor dryer?

A: Floor space, utilities accessibility and cost, and production requirements are the big things to think about. All of Vastex conveyor dryers use electric infrared heating elements and require a dedicated line. Warranty and capability to expand is also something to consider when selecting the brand of your Conveyor Dryer. Ideally, your dryer should be at least 4 inches wider than the decorated area to ensure a good cure. Wider belts, such as 54 inches, allow for two shirts to be placed across doubling your production capability.

Click here for Conveyor Dryers

A: Floor space, utilities accessibility and cost, and production requirements are the big things to think about. All of Vastex conveyor dryers use electric infrared heating elements and require a dedicated line. Warranty and capability to expand is also something to consider when selecting the brand of your Conveyor Dryer. Ideally, your dryer should be at least 4 inches wider than the decorated area to ensure a good cure. Wider belts, such as 54 inches, allow for two shirts to be placed across doubling your production capability.

Click here for Conveyor Dryers

|

Q: What are the electrical needs of the equipment?

A: Most conveyor dryers require 240 volts. Most flashes and drying cabinets are available in 120V and some smaller conveyors as well. Check the conveyor dryer production output to be sure it will meet your short and midterm goals. All electrical wiring should be handled by a licensed electrician to ensure proper installation. Our web site has electrical specifications on the back of each machine brochure. |

Q: If you are using a flash cure unit to cure, what should you do it on?

A: I recommend having a separate station behind you that you can rotate the flash underneath or over it and do it at a separate spot. We now offer the F-Flash Dual Rotary Pallet Table that is perfect for doing this. Q: How many shirts an hour is it reasonable to expect to be able to do using a flash cure unit?

A: I would think you could do somewhere in the range of 40 to 60 shirts an hour. |

Q: Once you get the dwell time figured out can you be pretty secure that it will be consistent or could it shift?

A: No, it shouldn't shift. Once you have determined the dwell time it should be pretty consistent. You should be setting the flash pretty close, within 2-3 inches of the shirt, and as long as you don't have the fan or a lot of airflow, it will stay very consistent.

A: No, it shouldn't shift. Once you have determined the dwell time it should be pretty consistent. You should be setting the flash pretty close, within 2-3 inches of the shirt, and as long as you don't have the fan or a lot of airflow, it will stay very consistent.

|

Q: I know a lot of people get started in their garage. What kind of electricity and plumbing needs are necessary to set up shop at home?

A: Your shop's size and equipment will determine your electrical needs. Even the smallest screen printer will need several dedicated power lines for each equipment. |

We recommend a dedicated Electrical Breaker or Control Panel for the Flash Cure unit and a separate dedicated breaker for your Conveyor Dryer. You should get a professional electrician to help with the wiring. We offer both Flash units and Conveyor Dryers that work in 120 volts. If you have 220-volts available then you can run larger equipment and increase your production. The use of 120-volt vs. 220-volt will have impact on your electricity costs. 220-voltage runs more efficiently.

|

Q: What about Water and Ventilation?

A: To set up your shop you'll need access to water. After exposure water is used to rinse and develop your image. When the job is completed screens need to be cleaned and image reclaimed. Regular garden hose pressure is enough to complete these tasks. However, implementing a Pressure washer will increase your production and amount of screens you can clean per hour. |

|

It's important to ventilate your work area, include a fan or implement an exhaust blower. Using Aerosols adhesives and also the reclaiming chemicals in the washout booth will leave a heavy smell in the work area.

Customers often ask us if they should ventilate their dryer, if your dryer has an exhaust blower you should connect an air duct and exhaust the heated air outside. You want good air movement around the shop so the exhaust fan can remove the smells out of the shop. Larger dryers have a built-in power exhausts that allow the user to pipe the air outside, smaller dryers may require after-market ventilation systems. |

|

Q: I have a septic system at the shop, what do I do about chemicals?

A: Screen printing shops will need to use chemicals to complete tasks such as Exposure & Screen Reclaiming. Alternative methods to cleaning screens such as Dip Tanks and Water Filtering systems are a viable option. Dip tanks are self contained chemical tanks to "dip" the screens to remove ink and emulsion before the final rinse. There are several water filtration systems available to aid in catching the majority of harmful byproducts from going down your drain. Depending on your location... as a screen printer you may be regulated locally by city agencies such as DERM and these steps will help you stay compliant.

|

Q: I'm looking for ways to offer more products and services to my shop. I understand a vacuum pallet would allow me to use my manual press to do a wider range of products. Can you explain how this works?

|

A: The Vacuum Pallet can turn your manual press into a sign and transfer printer. It's a special pallet that holes on the surface. It is available with a built in Blower or with the option to attach a wet/dry shop vacuum. The Vacuum sucks air down through the holes holding securely in place the printing substrates. With this pallet it's possible to print small signs such as Yard Signs, Foam Boards, Card Board & Poster Paper. You can also print Plastisol Transfers that can be stocked and later heat pressed on to T-shirts.

|

Q: What ink do I use for Yard Signs & other Flat stock graphic applications?

|

A: To print signs, you will need a special AIR DRY solvent ink which is compatible with those types of substrates and also air dries, visit our screen printing solvent based Air-dry ink section for more info about this ink series. Since in most cases, you will want to print both sides of the sign, you do not want to lay the sign down on a pallet sprayed with adhesive (this will gum-up your printed surface). The vacuum pallet holds the substrate in place while you are printing.

For additional requirements needed to get started in printing non-textiles, contact Customer Service at sales@floridaflex.com or call us at (305) 512-2222 for additional information. |

Q: What do I need to print Plastisol Heat Transfers

|

A: To print plastisol transfers, you will need Hot Split Transfer Plastisol Inks and Transfer Adhesive Powder. We also have a Hot Split Additive that is mixed into your plastisol ink to create your own Hot Split Ink. Transfer inks can be divided into two categories:

|

|

Q: How do I reduce the amount of spray tack that seems to get all over the shop?

A: Aerosol Mist spray can create over spray, other options such as Web Adhesive spray that provides more of a solid spray and or Waterbase Liquid pallet adhesive will helps to minimize the spray tack mess.

|

|

Q: I'm interested in any tips for speeding up cleanup in my shop?

A: A great way to speed up squeegee cleaning is by using masking tape. Use a good-quality masking tape to cover the handle and the section of the blade where it inserts into the handle. The tape prevents ink from migrating into the crevice between the blade and the handle and it also keeps the handle clean. When finished, it's quick to strip off the tape, throw it away and simply rinse off the remainder of the blade of ink and you're done. |

Q: I am looking at buying my first manual press. I noticed that some manufacturers offer an option called all heads down. What is this and what are the advantages?

A: An all-heads-down machine refers to a press where more than one print head can be lowered and locked into a pallet at the same time. For example, if it's a six-station, six-color press, all six screens can be locked down at once. Some presses are multiple-heads-down machines, while others allow you to put only one head down at a time. On a rotary manual screen printing press, you can lower down only one head at a time. Only one operator can print at a time on a rotary-load press. On an all-heads-down press, each pallet can be a single-color print station. So on a four-head, four-station press, you could potentially have four operators each printing a single-color job. The press doesn't rotate so each operator can work at his/her own pace.

A: An all-heads-down machine refers to a press where more than one print head can be lowered and locked into a pallet at the same time. For example, if it's a six-station, six-color press, all six screens can be locked down at once. Some presses are multiple-heads-down machines, while others allow you to put only one head down at a time. On a rotary manual screen printing press, you can lower down only one head at a time. Only one operator can print at a time on a rotary-load press. On an all-heads-down press, each pallet can be a single-color print station. So on a four-head, four-station press, you could potentially have four operators each printing a single-color job. The press doesn't rotate so each operator can work at his/her own pace.

|

If you wanted to do a two-color job on a four-head press with two operators, it would get more complicated. Each operator would have to work at the same speed as his partner because you would print the first color, then rotate the screens to print the second color. This can work but it can be a little tricky. However, it does allow you to get more production out of the press than the exact same size rotary-load press.

|

|

Q: When I purchase a Vastex manual press, can I install it myself or do I require a technician?

A: Installing a Vastex manual press does not require a technician and most customers install their own. As a Certified Vastex Dealer, we can come out to your shop and set up your equipment. The press is pretty easy to put together. V-100 & V-1000 models will require assembly, the V-2000 models ships mostly assembled some sections require assembly. All parts are numbered, for example: each "rotary arm" has a number that corresponds to a number on the "hub". Once all four arms are attached, install the pallet to each arm & complete by placing the print heads. |

|

Q: What is OFF-CONTACT and Why do I need Good screen tension?

A: What is Off-Contact? Off-contact is the amount of distance between the coated and imaged screen mesh and the substrate (the fabric or item on which you are printing). The proper amount of off-contact allows the screen to peel away from the printed substrate immediately or very soon after the squeegee has passed the image area. |

A: Why are OFF-Contact & Good Tension Necessary?

When screen printing, if you do not have enough off-contact the screen will not peel away from the substrate... this can leave rings or even stick, making the printed image smudged and useless. Another consequence of not having enough off-contact is a blurry image. Loss of details in the image also depends on mesh tension. Tighter mesh requires less off-contact because of how the mesh wants to snap or pull back from the image. Looser mesh requires more off-contact to get the mesh to pull away from the printed image which can create further distortion of the image.

When screen printing, if you do not have enough off-contact the screen will not peel away from the substrate... this can leave rings or even stick, making the printed image smudged and useless. Another consequence of not having enough off-contact is a blurry image. Loss of details in the image also depends on mesh tension. Tighter mesh requires less off-contact because of how the mesh wants to snap or pull back from the image. Looser mesh requires more off-contact to get the mesh to pull away from the printed image which can create further distortion of the image.

|

Q : How long should I expose my screens?

A: This is one of those questions that's it's tough to answer on a general basis because there are so many variables. You have to factor in thickness of the emulsion, type of emulsion, mesh count, color of the mesh, and humidity among other things. When I get asked this at shows, I recommend that the printer get an Exposure Calculator or use the Step Wedge Test. The Step Wedge is a modified exposure calculator. The exposure calculator is a piece of art and a filter that are placed together and burned for a specific amount of time. After exposure, wash it out and each section has a value, which will give you an exposure time. |

You will need to manually slide the light-blocking paper one block per minute, for about five or six blocks. Then when you are done exposing and washing out the image, read which time block had the best result. The exposure calculator is the more convenient and accurate way to get the optimal exposure time.

|

Q: How many colors do I need on my press?

A: The average printing job is one to three colors, but there are several advantages to getting a press with more than 4 colors. Being able to keep a 1 or 2 color job setup for a short period of time after delivery is good for those "Oops, I need 3 more Mediums!!" cases. Also, a popular multi-color process uses the 4 basic colors; Cyan, Magenta, Yellow, and Black. |

This means, if printing this process on anything but a white shirt, you will need a 5th color, white, as your under-base. But keep in mind, Vastex presses can be upgraded with additional color heads at any time.

|

Q: How can I do art work?

A: If you decide to do your own artwork, there are many Color Separation programs that will help you in this process. You will need a program such as Adobe Photoshop or Illustrator. If you do not have knowledge in color separation or working with these programs, we recommend to signup for our Training classes. You can also get a separation program such as T-SEPS which works in conjunction with Adobe Photoshop to separate your image. A rip program may be necessary to send the artwork to your printer. You will need to indicate to your customer the file format you work in if they supply their own art. |

|

Q: Where can I set up my equipment, and how much space do I need?

A: Your screen printing equipment can be set up in many different locations. You can use a garage, basement, an extra room in your house, or a commercial location. Our start-up shop's space requirements range from a 10' square area or corner of your basement, to a 12' x 16' room. It is beneficial to have access to running water in your location. |

|

Q : Where do I purchase T-shirt blanks and other apparel?

A: The best resource for locating a supplier in the industry is trade shows. If you are unable to attend a local trade show, industry magazines are another great resource for finding supplies. Impressions and Printwear magazine are the most popular. Here are a few local outlets in the South Florida area:

|

|

TSF Sportswear

Address: 1991 N Powerline Rd, Pompano Beach, FL 33069 Tel: (954) 691-9050 Online: www.tsfsportswear.com |

Mint Apparel - Yazbek Brands

Address: 1608 NW 84th Ave, Doral, FL 33126 Tel: 786-953-7631 Online: www.yazbekusa.com |

Got more questions...? call us or contact us by email by using the form contact form below...