- Home

-

Vinyl & more..

-

Heat Transfer Vinyl (Textiles)

>

- Vinyl & Letter Remover

- PU-FLEX 20in HTV

- PU-FLEX 13in HTV

- Easyweed 12in

- Easyweed Stretch 15in

- Easyweed Extra - Nylon

- Easyweed Electric 15in

- GLITTER Vinyl 20in

- Patterns HTV

- METALLIC & FOILS Vinyl 20in

- Glow in the Dark HTV

- Reflective HTV

- FLOCK HTV Vinyl

- Brick & PUFF 3D Vinyl

- Dye Sublimation Vinyl

- Printable Vinyl (Eco-Solvent)

- Transfer Application Tape

- T-Shirts & Blanks >

- Vinyl Cutters & Supplies

- Heat Transfer Press >

- Heat Press Accessories

- PSV Permanent Sticker - YARD

- Printable Sticker Vinyl

- Inkjet Transfer - Paper

- Sublimation Paper & Blanks

- Inkjet Printable - Vinyl

- Laser Transfer - Paper >

- Plastisol Transfer - Paper

- Screen Print Foils

-

Heat Transfer Vinyl (Textiles)

>

-

Inks & Supplies

-

Plastisol Inks

>

- Whites & Black

- Additives & Bases

- AP - All Purpose Inks

- HO/LB - Poly Low Bleed Inks

- LC - Low Cure Inks

- 4C - Process Inks

- SPT - SPOT Process Inks

- FL - Fluorescent Inks

- TF - HotSplit Transfer Inks

- GT - Glitter Inks

- MET - Shimmer & Metallics

- PMS - Pantone Colors

- PIM - PMS Mixing System

- REF - Reflective Inks

- PHS - Glow in the Dark

- PHC - Photo-Chromatic Inks

- SXF - Special Effects Inks

- Pad Printing Inks

- Latex Inks - Balloons

- Waterbase Inks

- Adhesives

- Spot Removers/ Cleaners

- Chemicals/Reclaim

- Emulsions

- Aluminum Frames

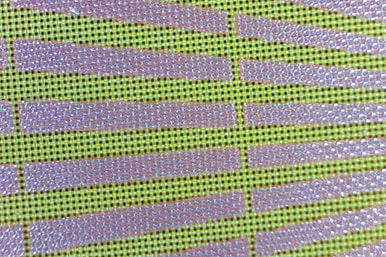

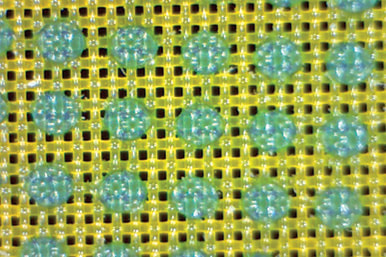

- Mesh for Screens

- Squeegees

- Screen Printing Supplies

- Output Film - Inkjet/Laser

- Color Separation Programs

-

Plastisol Inks

>

-

Equipment

-

DTF & UVDTF

- Gang Sheet Builder for DTF

- How to setup DTF Gang sheet

- Specs for DTF & UVDTF

- DTF Stock Designs

- DTF Printers >

- DTF Ink & Supplies

- UV DTF Printers >

- UV DTF Supplies

- Sublimation Printers >

- Mimaki Wide Format Printers >

- Heated Laminator

- Inkjet Printers

- Laser White Toner Printers >

- Vinyl Plotters/Cutters >

- Financing

- Specials

- Training

- Trade Shows

- Contact us

Emulsions and Screen Making Products

Selecting the right Emulsion

Customers always ask me, "what's the best Emulsion?" My answer has not changed in 20 years... there is no best Emulsion, only the emulsion that works BEST for you. The information below is here to help you in the process of making that selection easier! Feel free to call us if you need additional information.

|

|

To select the proper emulsion you must consider the following:

|

Photo Polymer vs. Dual Cure

|

Photo-Polymer Emulsions (Ready to use)

|

Dual-Cure Emulsions (Diazo Activation)

|

|

|

|

Flexi-Blue Emulsion is a Pure Photo-Polymer Direct Emulsion, ready to use with 43% solid content. Fast exposing and easy to reclaim. Recommended Exposure time: 40watt UV Bulbs = 35sec.

|

|

Flexi PINK Emulsion is designed specifically for the garment and textile industry. It's a durable, fast exposing Pure Photo-polymer emulsion that is easy to reclaim. This PINK Pure Photo-polymer direct emulsion resistant to plastisol ink, Excellent print definition on any mesh.

|

|

TEXTIL DW is an economical Dual-cure emulsion designed for plastisol & waterbase inks. Dual-cure emulsion with excellent durability, wide exposure latitude and very easy to reclaim.

|

|

Flexi Grafic DC Emulsion is a Dual-Cure direct emulsion for printing UV-cured, Plastisol, Solvent-based and Water-based inks. Stencils lack the typical tackiness found in Photo-Polymer emulsions.

|

Preparing stencils for Discharge Printing!

|

Ulano QT-Discharge Emulsion is specially formulated to resist discharge inks and is compatible with water-based and Plastisol inks too. It requires fewer coats than regular DUAL-CURE Water Resistant emulsions in the market today, providing good stencil every time.

|

|

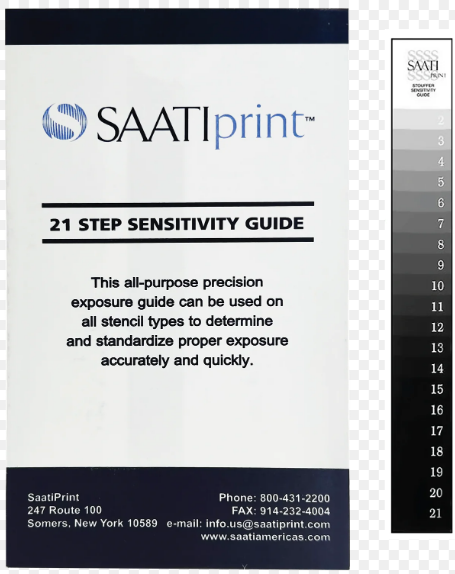

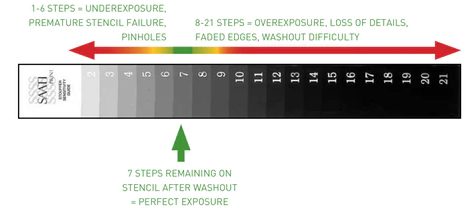

Exposure Calculators

This is the exposure guide of choice for accuracy, ease of use and all-purpose application. With the SAATI guide, there is no guesswork or complicated interpretation.

|

|

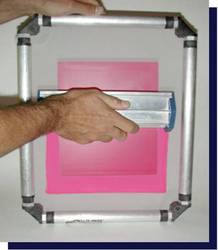

Metal ionized Double side Emulsion coaters, designed with a thinner side for a lighter deposit and a blunt side for a thicker stencil.

|

|

C1000 Semi-Automatic Screen Coater Achieve consistent & repeatable results, Holds screen lengths 23", 28", 31" & 36" (Height). Works with Wood, Aluminum & Newman re-tensionable frames. Simple foot pedal operation allows two hands on the coater for maximum control. Variable speed control, Quick height adjustment, No tools needed to make height or screen length adjustments.

|

|

FIXER #9 is a liquid stencil hardener formulated for use with all direct emulsion to improve its durability and water resistance. FIXER 9 can be used with other textile emulsions but will make stencil removal more difficult and may harden the stencil permanently.

OPTIONAL HEAT CURING: Drying FIXER 9 in heat will increase its water resistance. The higher the heat and the longer the dwell time, the greater will be the water resistance of the stencil. Suggested settings/dwell times: 100º F. (40º C.) for 3 hours; 140º F. (60º C.) for 1 hour.

|

INSTRUCTIONS:

- APPLY FIXER 9

Wear gloves, goggles, and protective clothing. Make a stencil with QT-DISCHARGE direct emulsion. Dry the screen and stencil. Apply Hardener D to both sides of the screen with a soft-bristled brush, a sponge, or a work rag. - ALLOW FIXER 9 TO DRY

Let he hardener dry at room temperature, without the use of a fan. Drying time will depend on the relative humidity, but may take up to one hour under high humidity conditions. Thorough drying allows time for the stencil to absorb the hardener and for hardener to evaporate from the open areas of the stencil. Any remaining hardener residue in open areas of the screen will usually open up after several prints, or can be removed with solvent - OPTIONAL ADDITIONAL DRYING TIME the water resistance of the hardener will be improved by allowing the screen to dry for a full 24 hours at room temperature.