- Home

-

Vinyl & more..

-

Heat Transfer Vinyl (Textiles)

>

- Vinyl & Letter Remover

- PU-FLEX 20in HTV

- PU-FLEX 13in HTV

- Easyweed 12in

- Easyweed Stretch 15in

- Easyweed Extra - Nylon

- Easyweed Electric 15in

- GLITTER Vinyl 20in

- Patterns HTV

- METALLIC & FOILS Vinyl 20in

- Glow in the Dark HTV

- Reflective HTV

- FLOCK HTV Vinyl

- Brick & PUFF 3D Vinyl

- Dye Sublimation Vinyl

- Printable Vinyl (Eco-Solvent)

- Transfer Application Tape

- T-Shirts & Blanks >

- Vinyl Cutters & Supplies

- Heat Transfer Press >

- Heat Press Accessories

- PSV Permanent Sticker - YARD

- Printable Sticker Vinyl

- Inkjet Transfer - Paper

- Sublimation Paper & Blanks

- Inkjet Printable - Vinyl

- Laser Transfer - Paper >

- Plastisol Transfer - Paper

- Screen Print Foils

-

Heat Transfer Vinyl (Textiles)

>

-

Inks & Supplies

-

Plastisol Inks

>

- Whites & Black

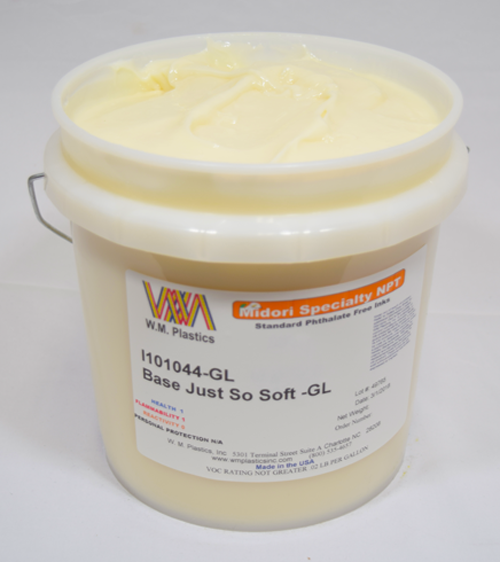

- Additives & Bases

- AP - All Purpose Inks

- HO/LB - Poly Low Bleed Inks

- LC - Low Cure Inks

- 4C - Process Inks

- SPT - SPOT Process Inks

- FL - Fluorescent Inks

- TF - HotSplit Transfer Inks

- GT - Glitter Inks

- MET - Shimmer & Metallics

- PMS - Pantone Colors

- PIM - PMS Mixing System

- REF - Reflective Inks

- PHS - Glow in the Dark

- PHC - Photo-Chromatic Inks

- SXF - Special Effects Inks

- Pad Printing Inks

- Latex Inks - Balloons

- Waterbase Inks

- Adhesives

- Spot Removers/ Cleaners

- Chemicals/Reclaim

- Emulsions

- Aluminum Frames

- Mesh for Screens

- Squeegees

- Screen Printing Supplies

- Output Film - Inkjet/Laser

- Color Separation Programs

-

Plastisol Inks

>

-

Equipment

-

DTF & UVDTF

- Gang Sheet Builder for DTF

- How to setup DTF Gang sheet

- Specs for DTF & UVDTF

- DTF Stock Designs

- DTF Printers >

- DTF Ink & Supplies

- UV DTF Printers >

- UV DTF Supplies

- Sublimation Printers >

- Mimaki Wide Format Printers >

- Heated Laminator

- Inkjet Printers

- Laser White Toner Printers >

- Vinyl Plotters/Cutters >

- Financing

- Specials

- Training

- Trade Shows

- Contact us

|

3000FF Curable Reducer

Curable Reducer is used to thin-down and extend plastisol inks that have harden over time, use instead of Soft Hand Clear to simulate waterbase effects. Add: 5%- to soften plastisol inks or up to 25% when printing thru higher mesh counts spot simulated process.

|

|

3015FF Plastisol Liquid Reducer

Liquid Reducer is a highly concentrated reducer used exclusively to soften or lower the viscosity of plastisol inks that have harden over time. Add: 1% by weight - Customers should be careful when using this product, do not exceed max allowance. |

|

3010FF Stretch & Fast Fusion Base

Stretch & Low Temp Additive is recommended when printing on Lycra, Spandex and other heat sensitive materials. Standard plastisol inks are not flexible enough for these substrates causing cracking or flaking. This additive helps to LOWER the CURING TEMPERATURE from 320F to 280F Add: 10-25% by weight - Addition in excess of 30% will affect opacity.

|

|

3060FF Long Life Nylon Catalyst - 8oz

Long Life Bonding Agent is a Nylon catalyst additive recommended to be mixed to plastisol inks when printing on Waterproof Fabrics, such as Nylon Jackets, Tote Bags & Umbrellas. Many other Nylon additives will shorten the life of your ink after mixed, our longer life when mixed at the recommended level will outlast all other nylon additives. |

Remember that once a catalyst is mixed in with the ink, the ink will have a limited pot life of 24hrs.

Mix: 5-10% by weight to any plastisol ink, only mix for production use.

Mix: 5-10% by weight to any plastisol ink, only mix for production use.

|

3090FF High Density Clear Gel

High Density Clear Gel is used to achieve a three (3) dimensional straight effects when printed with Thick Capillary Film. HD Clear Gel can be added in to your plastisol inks to create glossy effects. When printing us Recommended mesh: 86-110ct - To create glossy effects add: 20-30% to mixing colors.

|

|

3100FF Foil Printable Adhesive

Incorporate Foil to your designs by using Foil Adhesive you'll get a perfectly even peel and foil adhesion when applying your transfers. Screen print your foil adhesive, flash (do not cure) and proceed to the heat press to apply the foil. Recommended mesh: 86 - 110ct - Heat Press at 365 F for 10 secs @ Med/High Pressure.

|